KODIAK FLUID MANAGEMENT (KFM)

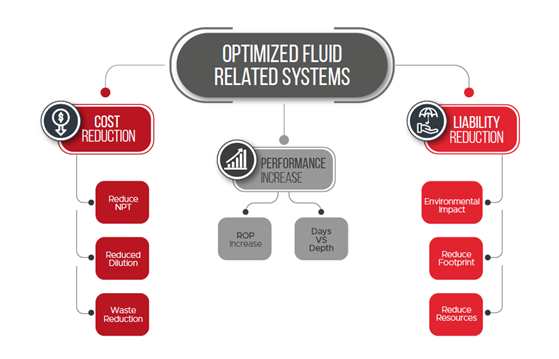

Our target is to identify and recommend options that can be translated into technical and economic optimizations

We provide senior consultancy in engineering directed to fluids processing optimization while drilling

SERVICES

We provide proven results using invoices to show cost savings – while most of our competitors only make projections that sometimes prove inaccurate. We provide real-time results that are tracked. We also utilize case histories to show exactly how we have helped other customers improve efficiency and save money. We deliver tangible proof that our customers can save significant money in the long run by taking an overall view and making a long-term investment in Kodiak Fluid Management services.

- Well Schematics

- Drilling Fluids Program

- OBW and WBM Reports

- Solids Control Reports

- Geology Master

- Cementation Program

- Service Companies Proposals, accepted after bid results

- Past NPTs Reported

- Tender Matrix Evaluation

- Correlationed Wells

Kodiak modern lab utilizes the latest technology in the oilfield services industry to help increase productivity and prevent problems – while also providing proven results. Combining powerful technology with highly skilled technical experts, we offer a Mud Lab in the field to provide comprehensive testing and analysis of drilling fluids. This allows us to provide customers with critical performance-tracking values and strategic efficiency monitoring. From field testing and determining whether or not the mud is performing properly, we are able to make adjustments and preventpotential problems – thus saving significant costs and increase the efficiency of yourdrilling operations.

- Fluid processing system audits to determine KPIs on site and following savings. Ex,

- installing flow meters to establish water consumption before optimization

- Evaluation on Drilling Fluids Program and its cost/efficiency convenience due to

- formation target.

- Waste stream generated either by past rigs on the block or projected according to

- hydraulic program.

- Permanent audits to Cementation Companies, program to apply, available

- equipment, cement quality and laboratory test.

In most instances, the aggregate volume of wastes will generally be ten to fifteen times the overall volume of the hole drilled – with the exception of cuttings volume, which will always equal the volume of the hole drilled. While cuttings volume cannot be reduced, all other waste streams can be lessened through proper application of the Kodiak fluid and waste management philosophy.

At Kodiak, we are dedicated to training our personnel and educating our customers about the advantages of embracing new practices. We are constantly working to develop new and better ways to reduce, reuse and recycle for the benefit of our customers, our industry and the environment.

- Rig Site Drilling Fluid Specialist

- Rig Site Solids Control and Waste Management Specialist

- Rig Site Cementation and Completion Specialist

- KFM Bogota based Advisors

The new DAK 1 technology, through a three dimensional polymeric network, efficiently encapsulates the free fluid, converting small particles of water into the dispersed phase, complying with the EPA 9095 B standard, drying and stabilizing water based drilling cuttings.