EOR

Services

TUNNEL PRO – ENHCEMENT OIL RECOVERY

Alternative well enhancement services centered around improvement and affordable Lateral Jet Drilling treatment. A viable alternative to traditional stimulation techniques.

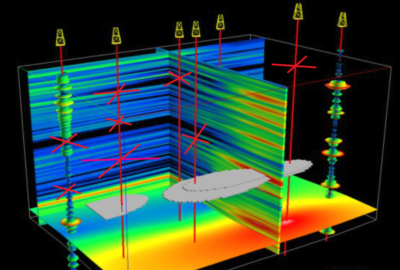

HYDRAULICALLY DRILLED LATERALS WITH DIFFERENT GEOMETRIES IN BOTH CONVENTIONAL AND UNCONVENTIONAL RESERVOIRS

The combination of jetting through problematical skin damage, and then creating a pipeline of tunnels back to the wellbore from out of the formation, is an exciting proposition BUT it does not apply to any kind of reservoir.

EMERGING TECHNOLOGY

Being able to steer laterals will mean that laterals can be drilled in wells where there is known oil/water contact. Presently, fracing isn’t an option for these wells.

OUR SERVICES

- Lateral Jet Drilling for Production increasement on mature wells

- Well Cleaning

- Fracking Guidance through Lateral Jetting

- Water injection Improvement

- Direct reservoir treatment with Chemicals

- EOR Engineering Consultancy

TUNNEL PRO

Technology designed for production enhancement of mature wells that can also be applied to new wells.

WELL CLEANING

Our well cleaning system is designed to deliver up to 16, 000 psi down a single hole. This cleaning process allows for a faster clean-out process.

FRACTURING GUIDANCE

The Laterals created helps the guidance of the fracking technology for the first 320ft after wellbore.

Wells up to 12,000ft deep

The laterals created improves water injection

Bypassing the damaged area with a jetted channel could reach up to 320ft into the formation

It can be used in conjunction with fracking, to deliver frac fluids to create an extra boost to the technique. It’s also suggested in carbonate formations, where acid (usually hydrochloric) can be added to the fluid to increase the impact of the radial penetration.

We have hands-on experience of working worldwide, including the North Sea, Russia/CIS, Africa, the Middle East, Asia & Pacific, and the Americas. Each of our consultants holds a senior professional qualification and has more than 20 years’ world-wide experience.

Oil & Gas wells

Our system will jet 4 laterals within 28/35 hrs maximum (not including gyro service)

We follow a multi-step process to ensure every part of your well is properly cleaned. The system is designed to pump any abrasive chemical down a hole up to 16,000psi

Let your chemical treatment reach beyond the damaged area and deliver it to improve the drain area of the well. Through the jetted laterals it can be done.

- We provide rigorous geoscience, engineering, and economic analysis to explore the feasibility of the technology on certain reservoirs.

- Portfolio and Technology

- Working with our customers to increase productivity, optimize their operations and reduce total cost of ownership through game-changing technology, services, and innovative collaborative commercial models.

- Tunnel Pro a FRAC LESS Solution.

JAVIER E. ARDILES – VP NEW TECHNOLOGIES

MAGNETIC FLUID CONDITIONER – MFC

Magnetic Fluid Conditioners (MFC’s) are tools that treat fluid using magnetic technology to control and prevent paraffin, scale, and emulsion. Using our patented technology 100% of production is treated as it passes through the MFC.

- Adequate magnetic strength

- Number of magnetic poles

- Sufficient fluid velocity through the MFC

- Orthogonal application of the magnetic field to the flowing fluid

- All metal components 100% high quality stainless steel

Due to the complexity of some flowing systems, we may need to adjust or enhance the MFC’s deployed in order to achieve satisfactory performance.

Placement of the tool is key in maintaining equipment. Downhole tools are installed in tubing or seat nipple or right above ESP or below the Rod Pump and surface units are placed at the well head or circulating pump.

Drawing of MFC for the Tubing

- Minimize or eliminate:

• Chemical treatments for scale and paraffin deposition.

• Hot oiling flowlines and production tubing.

• Downhole paraffin or scale cutting.

- Hot oiling flowlines and production tubing.

- Downhole paraffin or scale cutting.

- Stabilize production rates.

- Minimize downtime and increase present value.

- Minimize work overs and expensive treatments.

- Improve the quality of crude oil by eliminating emulsions in the storage tank or pipeline…thus, increasing value.

- Reduce corrosion by allowing inhibitor to reach pipe.

- The costs of one hot oil & chemical treatments for a single month could be more than the costs of a full year of Flo-Rite downhole tools, per well

- Since the tools treat the fluid mechanically instead of chemically,

- there is no chance of a chemical spill or possibility of chemical contact with humans or wildlife. There is no risk of electrocution due to the fact the tools require no external power.

- No MSDS required.

- No storage space is required for hazardous materials.