E-Line

Wireline Logging Services using new technology equipment and Logging tools for well intervention, reservoir evaluation, perforating and pipe recovery.

Services

Camera Logs

Features

- Fish eye technology 360° view always ensures full sight coverage in both memory and e-line (no moving parts).

- Simultaneous continuous downward and lateral sight coverage at bottom of logging string. Ensures faster operation, less time in hole.

- Internal storage capacity with a recording time of 24 hours.

- Zoom, Pan and Tilt functions in real time data and post job inspection in recorded data.

- Ability to see whilst pumping (coil operation) Enhanced chance of clear images.

- Multiple conveyance methods. Ability to convert between E-Line and Memory in the field.

- Cloud based image explorer and storage – Easy to share data with clients (WellViewwer Cloud).

- ComOn-site measurements capabilities.ponent & Subsystem

Camera Logs

Digital downhole camera solution for use in Oil, Gas and Geothermal wells. We combine digital images with advanced software processes in order to provide our customers with a visual log of their well.

Our WellViewer™ software is used on all cameras enabling unique continuous pan & tilt ability in the whole well bore.

The Vision WellCAM® platform can be run on all types of conveyances

Memory based interventions with up to 24 hours of recording time.

Low-bandwidth control images and full resolution images stored in camera.

Memory based interventions with up to 24 hours of recording time with the ability to flush while

Memory or live interventions on drill pipe with the ability to flush while recording.

Cased Hole Reservoir Evaluation

Features

- Porosity including clay free porosity.

- Saturation including the ability to differentiate between fresh water and heavy oil

- Clay Volume.

- Relative Permeability.

- Relative Bulk Density

- Dolomite identification in carbonate reservoirs

- Pyrite and calcite identification in clastic formations.

- Differentiation between bitumen and moveable oil.

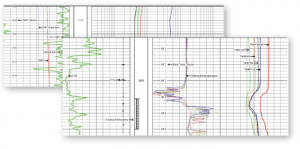

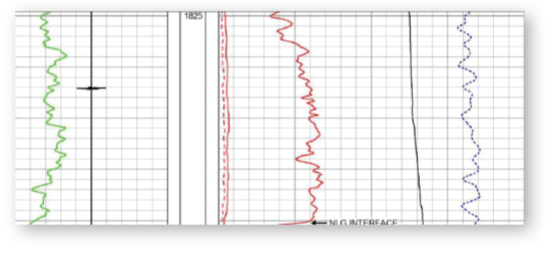

QUAD NEUTRON™ Thru Pipe Formation Evaluation

The Quad Neutron is a four detector nuclear measurement tool specially designed for through pipe reservoir evaluation. Two sets of detectors are positioned around a removable AmBe neutron source and housed in a 43mm OD down hole logging assembly called a Quad Neutron Tool (QNT), or “Quad”. Also in the Quad tool string are several supporting detectors. These include: Natural Gamma Ray, Split Spectrum Gamma Ray, CCL, Top and Bottom Temperature, Fluid Resistivity, and an Accelerometer. The Quad data bus and modular connector configuration enables attachment of many other detectors to be accommodated for specific applications.

Quad Neutron tool is used on high risk horizontal new drills and can log through drill pipe, case and then log. It’s also a great tool for cased reservoir management wells and can identify areas with high water saturation and bypassed hydrocarbon. Applications for shale oil and gas formations, formation water salinity determination and fracture planning and evaluation can also be done with this tool.

Cement Bond Logs

Features RIb & HD RIb

- 1.5ft spacing map sensors

- Slip joint and bi-metallic isolator bar construction

- Industry leader in high definition cement mapping

- Wellbore and internal temperature sensors

- Rigid V-Slot Isolator Bar incorporated into the tool body

- 450°F (204°C) flasked version available

- VDL crystal at 6ft to increased depth of investigation

- Compatible with Titan Compensated Neutron, GR-Neutron and CCL

Radial Incremental Bond & High Definition Radial Incremented Bond – HD-RBT

RBT Conventional dual spaced 3ft-5ft CBL is an economical way to evaluate a cement job. Radial Incremental Bond (RIB) tools provide the conventional CBL-VDL receivers plus additional directional radial receivers that can measure circumferential data necessary to determine if there is channeling in the cement.

RBT provides assessment of cement bond quality and hydraulic isolation, identification of micro annulus and channeling and locates top of cement (TOC)

Pipe Recovery

BENEFITS

- Clean cuts provide operators with simpler, quicker recovery operations.

- High success rate for first attempt cuts.

- Can provide a cutter for every scenario. Customization of cutters available upon request.

- “Air shippable” at Class 1.4S.

- Conforms to API RP-67.

- Can be run through heavy mud, paraffin, collapsed tubing, and reduced restrictions.

- Can be run 4X faster than conventional jet cutters.

- Must be run decentralized to maximize effectiveness of tool.

Split Shots & Jet Cutters

Owen’s Split ShotR Cutter was designed for use where traditional jet cutters were not effective or could not be used. The Split ShotR Cutter is run in a linear configuration adjacent to any collar or connection and positioned by inline magnets. After detonation the collar or connection is split allowing the pipe to be freed for easy removal.

- Compatible with Control Fire and select RF-safe igniter systems.

- No conveyance limitations.

- World’s largest range of cutters.

- Cutters can be customized to specific situations

Jet Cutters

Applications

- Pipe recovery operations.

- Low pressure gas well tubing recovery.

Features

- Cleanest cuts in the industry, with minimal flaring.

- Rated up to 400 °F, 22000 psi (2040 °C, 152 Mpa).

- Clean cuts in low pressure gas wells utilizing advanced technology.

Features

- Provides a survey which accurately locates the stuck point. Includes CCL assembly.

- Solid-state electronic motor controls sense overload in the system and limit the current.

- Senses full open or closed condition of the foot assemblies.

- Sensor picks up compression, tension or torque movements from the pipe.

Free Point Indicator Tool (FPIT)

The FPIT free-point indicator tool with combined backoff shot determines the free point in stuck drillpipe, drill collars, tubing, or casing and then provides the force that frees the stuck assembly. The FPIT tool provides accurate information about the stuck assembly, saving you both time and money because you can make immediate and informed decisions.

During the course of drilling or workover, the work string can become stuck in the borehole for many reasons: hole conditions, formation characteristics, mud properties, mechanical problems, assembly tools, or operational error. Saving the well and reducing expense means freeing the stuck assemblies quickly and efficiently. The FPIT tool determines how much of the stuck assembly may be freed. In combination with a backoff shot, the FPIT tool efficiently frees the stuck section of the assembly by applying an explosive shock inside a tool joint to which left-hand torque has been applied. Up to seven strands of Primacord detonating cord can be used for the combined operation’s explosive load.

Benefits

- Non-Explosive

- Radio Safe

- Operates in temperatures to 500°F (260°C) & pressures up to 10,000 psi (68.94 MPa)

- Cuts all steel, high chrome, plastic coated tubulars, Inconel®, Monel®, Hastelloy® and exotic pipe

- Non-hazmat fuel systems available

- Cuts are flare-free and do not produce swelling

- Cuts in fluids or dry pipe, heavy muds and weighted drilling fluids

RCT Tools Are Available For

- Standard severance applications

- Undersized for restrictions

- HT environments (XRT® Radial Cutting Torch Tool series for HPHT

deployments*) - Cutting up to 9-7/8” casing

- Custom tools available

Production Logging

Features

- Cage sizes available 1.68”(4.29 cm) – 2.125”(5.40 cm) – 3.00”(7.62 cm).

- Tool connections Standard: 1 3/16 -12 GOI

- H2S resistant material

Flow Meter Spinner

The continuous flow meter spinner incorporates an impeller rotated by moving fluid. The impeller is mounted on precision bearings. Rotation is detected with three zero drag Hall Effect devices. The flow meter is run below a telemetry section which supplies power to the tool and transmits flow data to surface. The flow meter operates in vertical or horizontal positions and outputs both up and down flow. The flow meter may be run simultaneously with all other production logging tools.

Applications

- Production profiles.

- Injection profiles.

- Casing and tubing leak detections.

- Gauging effectiveness of well Treatments

Features

- The noise logging tool is essentially a sensitive high-fidelity microphone. The piezoelectric crystals are housed in an oil filled chamber. A piston is used for pressure compensation

- These tools work with all multiple band noise logging systems. The warrior logging system divides the frequency spectrum into four frequency ranges.

- The option is available for cutting the gain of the downhole tool by a factor of 10 for use in wells with very high noise levels.

Noise Temperature Tool

Kodiak’s noise tool is primarily run in a cased-hole producing well environment and uses microphones to detect fluid movement. Noise is created from fluid flow inside the casing or behind the casing. Changes in noise are created as the flow rate changes or the pressure changes. The flow rates change as fluid migrates into one channel from multiple sources. Pressure changes are usually the result of an obstruction or opening in the casing. The noise log, therefore, is used for detecting channels behind the casing, flow into casing, flow out of casing, or obstructions inside the casing. Noise logs are typically created by taking multiple stationary samples and combining the data into one continuous log.

Measurements are usually taken when the tool is stationary because with the tool moving, the microphones would pick up all the road noise. The noise tool is commonly stacked with a gamma ray, casing collar locator (CCL), and temperature tool, but these tools are typically powered up using opposite polarity, enabling the noise tool to be powered up individually and recorded separately without being corrupted by electronic noise from the other tools.

Stand Alone Encoder

- Records a memory depth log

- Setup and data recovery via USB

- Displays live depth and speed

- Intrinsically safe unit

- Rechargeable internal batteries

ScarletPL - PLT / ILT

Innovative, advanced and compact logging tools with its specific Data Acquisition system.

Quick and easy to rig up. The ScarletPL logging suite provides all readings you need to acquire all precise Production Logs for your well and reservoir.

Half the size of conventional tools with Twice the performance during operations!

Surface Readout Unit

- Merges depth with tool data in real time

- USB interface to laptop

- Automatically setup

Caged and FullBore Flowmeter characteristics:

- 1-11/16” and 2-1/8” ODs

- Near Zero drag bearings

- Ultra-Light impeller

Features

- Realtime or Memory acquisition modes.

- GR-CCL - for correlation.

- Tension - Compression Sub for CT logging, tractor logging and wellbores with restrictions.

- Pressure Tool – Available with Quarts or Sapphire Gauge.

- Temperature Tool – High speed RTD.

- Acoustic Density Tool – High accuracy and reliability, dynamic not affected bay deviation.

PLT / ILT

Kodiak’s extensively field proven Production Logging Tools with multiple sensors that provide the customer with highly accurate data sets of downhole production information which describe the behavior of fluids in the well. The PLT string can be run in realtime or in memory mode.

QFT Tool

Features

- No wellbore storage effect

- No surface measurements needed

- Slickline conveyed

- Fast results

QFT Tool

The Quick Formation Testing (QFT) tool array by DPT provides a unique and simple solution to determine reservoir properties such as initial pressure, skin effect, and formation damage amongst others, by using transient pressure analyses combined with fluid samples evaluation and proprietary interpretation techniques.

Technical Specs

| For Tubing/ Casing sizes: | 2-3/8”, 2-7/8”, 3-1/2”, 4-1/2” 5”, 5-1/2” |

| Pressure: | 15,000 PSI |

| Temperature: | 350°F |

| Tool O.D. (excluding seals): | 1.75” |

| Tool String Length: | 12’ |

| Fluid Sample Volume: | 600cmᶾ |

| Sensor Resolution: | 0.0003% F.S. |

| No. of Samples: | 1 Million |

| Communication: | USB |

Tubing Conveyed Perforating (TCP) Select Fire Options

TCP SELECT FIRE OPTIONS

- Time Delay

- Time delay with pressure.

- Gun Control Line System.

- Gun Release / Remote Fire.

- Motor Heads.

- Retrieving Tools

Tubing Conveyed Perforating (TCP) Select Fire Options

Tubing Conveyed Perforating (TCP) is a cost effective way for well completions in vertical, deviated or horizontal wells. Utilizing tubing conveyed perforating (TCP) systems; gun lengths are not limited, can be run on coiled tubing or jointed pipe saving time in rig cost as well can be left on the tubing sting allowing the producer to get well on production sooner.

Kodiak has many options of tubing conveyed perforating (TCP) systems to meet all your service needs, as well all systems can be catered to meet the customers’ requirements.

TCP EQUIPMENT OPTIONS

- Control Line TCP systems.

- Annular Pressure Operated / Production Vent.

- Annular Pressure Packer Bypass.

- Automatic Gun Release.

- Ball Drop Hydraulic Actuated Firing Head.

- Direct Pressure Firing Head.

- Drop Bar Hydrostatic Firing Heads.

- Drop Bar Operated Production Vent.

- Dual Top Annulus Differential Pressure Firing Head.

- Dual Top Firing Head.

- Fill/Stop Fill Valve.

- Firing Bodies and Pup Joints.

- Gun to Gun Transfer with 6 Minute Delay.

- Mechanical Gun Release.

- Ported Debris Barrier Sub.

- Underbalance Sub.

- Ported Debris Barrier Sub.

- Motor Heads.

- Retrieving Tools.

Well Integrity

Features

- Available in 24, 40 or 60 finger versions

- Surface readout or memory options

- Combinable with other Ultrawire tools

- 3D data analysis using WIVA software

- Statistical analysis using WIPER software

- Extended finger lengths available for all tools (optional)

Multifinger Imaging Tool - MIT

The MIT is available in a range of diameters to suit varying casing/tubing sizes. The number of fingers increases with the diameter of the tool to maintain maximum surface coverage. The tools can be run in combination with other Well Integrity instruments

MIT data can be used to generate 3D images of pipe condition using Kodiaks visualization software Well Integrity Visual Analysis (WIVA). Well Integrity Processing, Evaluation & Reporting (WIPER) software can also be used to make a statistical analysis of the pipe condition.

Magnetic Thickness Tool – MTT

The Magnetic Thickness Tool surveys variations in pipe metal thickness. Twelve sensors are mounted on the inside of a set of bow springs, allowing the tool to pass through tubing and log pipe sizes up to 9 5/8” casing.

MTT provides accurate measurements of the internal diameter is extremely effective, but is not the complete story. Many instances of corrosion damage are on the outside of the casing / tubing. Then, the tool provides a measurement of Metal loss on outside of casing.

Features

- Pipe inspection for internal & external metal loss.

- Surveys wall thickness.

- Optimized results using MIT data for internal diameter.

- Logs casing below tubing due to bow spring design.

- Simultaneous operation with other Sondex UltrawireTM tools.

- Surface read out or memory logging.

- Visualization using WIVA 3D imaging software.

- Processing, Evaluation and Reporting with WIPER software.

Wireline Perforating, Plug And Abandonment

Features

- Combinable with other tools.

- Depth control in casing or tubing.

- Location of casing or tubing damage.

- Confirmation of perforation depths or intervals.

- Available in full range of sizes to accommodate correlation of different sized devices.

CCL & GR Perforating Casing Collar Locator - Perforating (CCL)

As the tool passes a collar, or change in metal volume, lines of magnetic flux between two opposing permanent magnets are disturbed. This causes a low frequency voltage or Electro Magnetic Field (EMF) to be induced in a coil, mounted between the permanent magnets. Finally the signal is converted by a voltage-controlled oscillator for recording in the section of the tool.

Features

- H2S Resistant Material.

- Enables GR correlation whilst shooting.

- Engineered for use at high temperature.

- Depth control in formation GR, casing or tubing.

- GR & CCL Confirmation of perforation depths or intervals.

- Flasked version available for extreme high temperature

Gamma Ray – Perforating (GR)

Tool with a Scintillation sensor that detects the gamma rays that coming from the formation. This measurement can localize the zones with presence of hydrocarbons and water, allowing to confirm the shooting interval. Kodiaks range of Gun Gamma Rays allows to perform the GR-CCL log whilst perforating, this can save rig time also its ideal for use in any situation where a standard CCL log is not possible.

Applications / Benefits

- Natural flowing and stimulated wells.

- Sand control and gravel-pack completions.

- Production and injection wells.

- Damaged formations.

- All reservoir types.

- All fluid types (oil, water, gas).

- Improves well performance.

- Capable of lowering skin factors allowing improved production or injection.

Perforating Gun Systems

Maximized productivity from your well depends on getting the perforations right, located in the productive interval, correctly oriented, deep and clean, our hollow carrier and capsule perforating guns are engineered systems that are optimized for the wellbore environment, reservoir, and completion geometry.

Capsule Guns: exposed gun systems, with the individual shaped charges sealed in pressure-tight protective capsules mounted on a carrier strip or links that are exposed to the well environment.

Expendable and Retrievable systems: the two types of capsule guns are expendable (the charges and mounting assembly are left as debris after firing) and retrievable (debris is left, but the mounting is recovered for use where debris is a concern).

Super Deep Penetrating (SDP) charges: offer unbeatable penetration when compared to conventional shaped charges while maintaining excellent hole diameter. These large holes assure greater tunnel volume beyond the damaged zone allowing for enhanced flow and productivity.

Good Hole (GH) charges: are unique in that they offer a perfect balance between larger hole diameter while retaining very good penetration.

Big Hole (BH) charges: produce the maximum hole diameter and area of flow while keeping an effective penetration, perfect for gravel pack or frac pack operations.

Benefits / Features

- Helps reduce fracture break down Pressure.

- Potential reduction in weak sand production.

- No incremental cost required to upgrade existing hardware.

- Wide variety of charges to meet specific needs.

- Super deep penetrating charges perforate beyond the damaged zone.

- Greater formation contact created by bigger holes.

- Big hole charges optimized for gravel packs.

- Compatible and best used with all existing Hunting Titan wireline and TCP systems.

- Can be deployed using all conveyance methods. Available with RDX, HMX and HNS

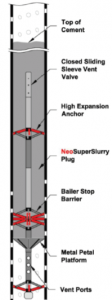

Benefits

- Each Wide Range T-TBP sets in a wide range of casing sizes.

- Successful setting and anchoring is verified on the setting run.

- Bailer Stop allows precise setting depth determination on setting run.

- Bailer Stopnot allow bailers to descend to the metal-petal-platform.

Thru – Tubing Bridge Plug (T-TBP)

T-TBP pass thru small diameter restrictions and can set in diameters up to 8 times their run-in diameter. Cement slurry is placed atop the plug to achieve long-term pressure isolation. Over 30.000 WL-run T-TBPs have been successfully run throughout the global oil industry.

Applications

T-TBPs can run on WL, Slickline and CT. They provide a platform upon which SuperSlurry cement is placed. The cement sets and bonds to casing, therein, providing a long term high ΔP casing plug

WideRange T-TBPs provide zonal isolation in: perforated intervals, saltwater wellbore fluids, hot dry natural gas and crude oil and gas condensate. SuperSlurries are available in 17ppg, 18ppg & 20ppg slurry weights. SuperSlurries, high shear-bond expanding cement formulations, are placed atop WideRange T-TBPs. The combination of the two provides zonal isolation for the life of the well.

Benefits

- Added Level of Safety – detonator is never electrically connected until specific software command is sent.

- Non Sequential Operation – independent switch that does not rely on previous gun success.

- Skip Over Capabilities – provide valuable time savings as perforating operations can continue in the case of a gun misfire.

- Positive Shot Indication – confirmation of firing, especially in deep, horizontal well conditions.

- User Friendly System – avoid user positive/negative wiring mistakes leading to off depth perforations.

- Eliminate Premature Activation – gun flooding causing piston activation leading to off depth perforations.

Selective Firing & Pump Down

Kodiak provides customized completions systems and well application systems to meet unique customer needs and well applications. With the increase in horizontal and non-conventional well completions new solutions for customers was obvious.

Pump down / select fire IP addressable systems coupled with Tool disconnect services

Benefits

- Eliminates burdens related to use and transport of explosives.

- Exceptionally simple to run and maintain.

- Expendable are 2 fl-oz of hydraulic fluid per run.

- 1-11/16” RT can deploy 1-5/8” thru 9-5/8” non-explosive WideRange Thru-Tubing Bride Plugs.

- RTs can be run on WL and Slickline (with a downhole power supply)

Release Tool (RT) Non Explosive Thru Tubing Zonal Isolations

RTs provide the ability to deploy non-explosive WideRange Thru- Tubing Bridge Plugs rather than the conventional explosive-deployed Thru-Tubing Bridge Plugs. RTs thread to the top the WideRange Thru-Tubing Bridge Plugs and are actuated by the application of DC power sent down the WL or from a downhole slickline power supply. Actuation requires approximately 275-300 mA at service conditions.

RTs are reusable. Redressing a RT only requires replacing O-rings.

RTs assure non-explosive deployment of WideRange Thru-Tubing Bridge Plugs

Applications

The RT Standard and HPHT/UHPHT Service models are available for sweet, sour and acid gas service conditions.

Benefits

- Field replaceable control cartridge.

- Quick & easy re-dress between runs.

- Suitable for depleted reservoirs.

- Can be activated with positive or negative pressure pulse code e.g. TCP or Coiled tubing operations.

- Can be activated with preprogrammed accelerometer burst e.g. Slickline operations.

- Accelerometer can be disabled for TCP operations.

- Option available for long duration TCP battery pack.

- Can deploy and initiate all industry standard ballistic devices.

- Fully (3rd party) RF, lightning and stray voltage safe via a Certified Safety Assessment.

- Design has been Vibration & Shock tested to 40G

Perforating Trigger

The Quick Change Trigger (QCT) is designed to fulfill the need for a cost effective triggering device, without compromising on quality, to initiate all types of explosive and pyrotechnic devices, regardless of the method of deployment. The tools concept has been based around quick & easy cartridge changes if required at the well site and this can be performed with no specialized tools. The QTC would be suited to lower pressure zones where deployment is via TCP, Coiled Tubing or Slickline due to its selective control pulse window.

Cartridge inserts are available for firing a wide range of ballistic devices used in the following applications:

Applications

- Casing perforating.

- Tubing punching.

- Tubing cutting.

- Plug/Packer setting.

- Downhole sampling.

- Various other downhole operations.

Features

- The PD bailer system does not require explosives, providing safer operations.

- Positive displacement ensures accurate placement, even in deviated wells—enhancing efficiency.

- The system provides a clean dump every time, resulting in no stringers to interfere with subsequent operations.

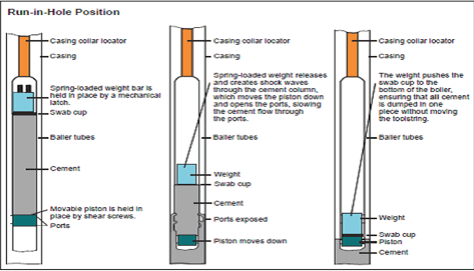

Dump Bailer-TT

Dump bailers for cement, acid, or sand dumping operations are offered in two types—the positive-displacement (PD) bailer and the gravity-feed bailer. Dump bailer uses a weighted swab piston to push, or positively displace, the bailer’s contents into the wellbore. The dump bailer does not use any explosives. Instead, a solenoid drops a weight bar from a set of collets, causing a pressure wave that moves a piston in the bottom of the bailer to release the cement. This advantage helps to make the system technically superior to other positive-displacement systems in the industry. The gravity-feed system is the most commonly used dump bailer in the industry. The gravity-feed system requires explosives to shatter the disk in the bottom of the bailer, enabling the cement to flow.

Gravity-Feed System

- The system’s simple design requires minimal user training, is easy to operate, and uses an explosive charge to release cement downhole—all help to control costs.The absence of internal moving parts makes the system easy to maintain, saving time.